Button feeling for touch displays

We proudly present our new haptics developer kit. Gain insight into our innovation in the following article by Michael Nussbaumer and Patrick von Unold.

Development kit simplifies the construction of touch solutions with haptic feedback

More and more touch display users want haptic feedback to get a comfortable feel and the certainty of error-free operation that is similar to mechanical buttons. The distributor and system integrator next system offers a haptic developer kit as a quick entry point.

From Michael Nussbaumer and Patrick von Unold

With its haptics developer kit, next system is pursuing the goal of simplifying entry into the world of haptics and at the same time enabling integration that is also suitable for series production. Thanks to the kit’s scalable and modular design, users can use different display sizes, quickly create samples and make flexible adjustments. The kit is designed to help them not only understand the benefits of haptics in theory, but to experience and “grasp” them in real life.

An important function of the haptic actuator used by next system is to imitate the sensation of a mechanical button. This is achieved by moving the touch surface in the direction of movement of the finger (Z-axis). Users of the kit can adjust all the key parameters to achieve the most suitable behavior for them.

If the kit is combined with a customer-specific display with touch, customers can develop their own application and test it immediately. For example, next to the various button functions, simulations of sliders or rotary encoders are also possible.

Functionality of the piezo actuator

A piezo actuator is based on the piezoelectric effect, which enables the conversion of electrical energy into mechanical movement. As soon as voltage is applied to the piezo element, it leads to deformation of the piezo crystal and the piezo element expands in one axis. This phenomenon is used to generate mechanical movement.

To generate an even greater deflection – and therefore a more intense haptic effect – a type of cymbal or other suitable mechanism is used that generates a greater movement in the desired direction. In addition to the greater deflection, the result is also a high acceleration of the surface to be moved. This helps to ensure that the haptic feedback perfectly mimics the effect of pressing a mechanical button.

The piezoelectric effect can also be reversed: By applying force, the piezo crystals are mechanically deformed, generating a measurable voltage. This makes it possible to detect and evaluate the applied pressure. One advantage of this method is that only one component is required. However, only dynamic changes are detected because the “piezo-creep” effect occurs with prolonged pressure and the voltage drops to 0 V again.

The “Capsense” capacitive sensor solution is based on the formation of a plate capacitor with an air gap between two conductive surfaces that measure changes in electrical capacitance. This makes it possible to detect slow changes and realize precise force measurement.

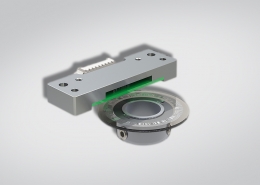

Actuator module

Several components and functions are integrated in the patent-pending actuator module M1:

- Piezo as a mechanical feedback sensor and for dynamic pressure detection – the piezo from TDK is used both to generate haptic feedback and to detect the pressure applied.

- The Capsense solution ensures precise and static force measurement.

- A defined spring preload is used to properly mount the piezo and create a force-displacement system that ensures stable and reliable actuator movement.

- Housing for easy mounting – the actuator module is equipped with a housing that allows easy screwing or gluing into the end product, ensuring safe and easy integration.

- An additional, customizable damping element reduces the noise generated by the high acceleration of the actuator module and at the same time extends the path of the movement to achieve higher performance and a clearer feel.

The actuator module is already in series production. This way, the simple prototype construction and a problem-free conversion to a series product is always guaranteed.

Breakout board, controller and API

The supplied PCB kit (breakout board) is specially designed for a 7-inch display and can also be used for other display sizes by separating the individual actuator modules. All users have to do is fit a pin strip or solder a cable directly. The signals are brought together and connected to the controller from that point. In this way, the kit can be flexibly adapted to different display diagonals.

At the heart of the haptic controller is the firmware that generates the output signal and evaluates the pressure measurements for piezo sensing and Capsense. The firmware includes logics that can take into account temperature or environmental changes in Capsense and enable the activation of different piezo sizes. The API provided has a generic structure so that other haptic actuators such as electrostatics or solenoids can also be controlled in the future.

The standard controller requires a supply voltage of 12 V (DC) and offers USB, I²C and RS-232 interfaces for communication with the host computer, which processes the data. It is also possible to integrate the controller or firmware more deeply into a customer-specific application. For this purpose, next system provides the circuit design for customer projects to enable seamless integration.

The packaging of the kit not only serves to secure it during transportation, but also offers the option of placing a display/touch module on it and combining it with haptics and force measurement thanks to the “ready-to-start” pre-assembly of the components.

A configuration tool, which makes it possible to play back various haptic profiles and set the values for force measurement, is included in the scope of delivery. This makes it easy for users to vary the behavior of the actuator by adjusting the parameters to optimize a system for the planned application.

Project implementation: HUI instead of GUI

One of the biggest challenges when implementing GUIs (graphical user interfaces) with haptic feedback as an additional option is to make the best possible use of the new possibilities offered by haptics. In terms of hardware, integration is relatively simple with the help of next system’s series-capable actuator, but it requires appropriate support from the software and the user interface. According to the motto “HUI (Haptic User Interface) instead of GUI”, the technology enables a wide variety of use cases and functions.

The force measurement allows users to delve deeper into menu levels and avoid unwanted touches or ghost touches. Haptic feedback offers optimized operating safety and increases the comfort of touch operation similar to a mechanical button. The combination of these two elements enables intuitive and user-friendly interaction. Users receive support from next system when implementing projects.

Outlook

The Haptic Developer Kit is an essential step to get started with haptics. It enables the integration of a component for a haptic user interface. In addition, there are plans to provide a suitable 7-inch display with PCAP touch and a mounting frame by the end of this year. This display/touch solution can be mounted on the actuators to enable seamless integration of haptics and touch functions and make initial tests within an application even easier.

Source: https://wfm-publish.blaetterkatalog.de/frontend/mvc/catalog/by-name/ELE?catalogName=ELE2319D

Share Article

next system

next system

next system & SEPA

next system & SEPA